Titanium and its alloys

-Chemical Properties

Corrosion Resistance:

Forms a passive oxide layer (TiO₂) in air/water, resisting:

Seawater, chlorides, acids (except HF/H₃PO₄).

Applications: Desalination plants, marine hardware.

Reactivity:

Burns in pure oxygen (>1,200°C) – used in pyrotechnics.

Biocompatible (non-toxic) – ideal for medical implants.

-Thermal & Electrical Properties

Thermal Expansion: 8.6 µm/m·°C (low; reduces thermal stress).

Superconductivity: Becomes superconducting at <0.4 K (niche cryogenic uses).

🔹 OEM/ODM Titanium Services in Tinog Trade

1. Custom Titanium Product Manufacturing

Materials:

Pure Titanium: Grade 1, 2, 3, 4

Titanium Alloys: Ti-6Al-4V (Grade 5), Ti-3Al-2.5V (Grade 9), Ti-15V-3Cr-3Sn-3Al (Beta alloy)

Special Alloys: NiTi (Nitinol), Ti-Cu, Ti-Mo

Product Forms:

Semi-Finished: Plates, sheets, bars, rods, wires, tubes, forgings

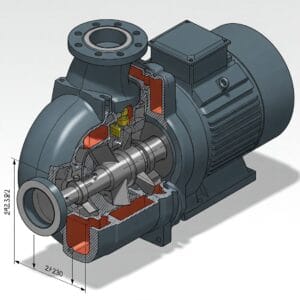

Precision Components: Fasteners, flanges, valves, heat exchangers, surgical implants

Complex Structures: Aerospace brackets, marine hardware, custom machined parts

2. Baoji’s OEM/ODM Capabilities

Service Details

Material Selection Advise on optimal titanium grades for corrosion resistance, strength, or biocompatibility.

CNC Machining High-precision milling, turning, drilling, and threading for tight-tolerance parts.

Sheet Metal Fabrication Laser cutting, bending, welding (TIG, MIG, EB welding).

3D Printing (AM) Selective Laser Melting (SLM) for aerospace & medical prototypes.

Surface Treatment Anodizing, sandblasting, polishing, PVD coating, passivation.

Quality Certification ISO 9001, ASTM B348, AMS 4928, RoHS, REACH, FDA (for medical devices).

3. Why Choose Baoji for Titanium OEM/ODM?

✅ Cost-Effective – Lower labor & production costs than Western suppliers.

✅ Fast Prototyping – Rapid sample delivery (1-2 weeks for simple parts).

✅ End-to-End Solutions – From raw material sourcing to final assembly.

✅ Industry Expertise – Decades of experience in aerospace, medical, and industrial titanium applications.

🔹 Target Industries & Applications

Industry Typical Titanium Products

Aerospace Jet engine components, landing gear, airframe structures.

Medical Bone screws, dental implants, surgical instruments.

Chemical Heat exchangers, reactor vessels, piping systems.

Automotive Exhaust systems, turbocharger wheels.

Marine Propeller shafts, submarine components.

Energy Offshore oil rigs, hydrogen storage tanks.

🔹 How to Work with Baoji Suppliers?

Submit Design/Requirements – Provide CAD files (STEP, IGES) or samples.

Material & Process Confirmation – Engineers recommend the best alloy & fabrication method.

Prototyping & Testing – Small-batch samples for validation.

Mass Production & QC – Strict inspection (UT, X-ray, chemical analysis).

Global Logistics – Shipping via DHL/FedEx or sea freight.

📌 Contact Baoji Titanium Manufacturers Today!

Looking for a reliable titanium OEM/ODM partner? Baoji suppliers offer:

✔ Competitive pricing (30-50% lower than US/EU).

✔ Custom alloy development (e.g., high-strength or high-temperature grades).

✔ One-stop titanium solutions – machining, welding, finishing.

📩 Request a Quote: Share your specs (material, dimensions, quantity) for a fast response!

📍 Key Fact: Over 60% of China’s titanium is produced in Baoji, making it the best sourcing hub for global buyers.