Fijaciones de aleación de titanio para aeronaves

Aerospace & Defense

• Mission• Critical Components Manufactured with Praxis Proprietary Technology

• Praxis components use TiRx Grade 5 titanium.

• Superior strength to weight ratio.

• Offers performance and weight savings for fuel costs.

Titanium Components For Aircraft Interiors

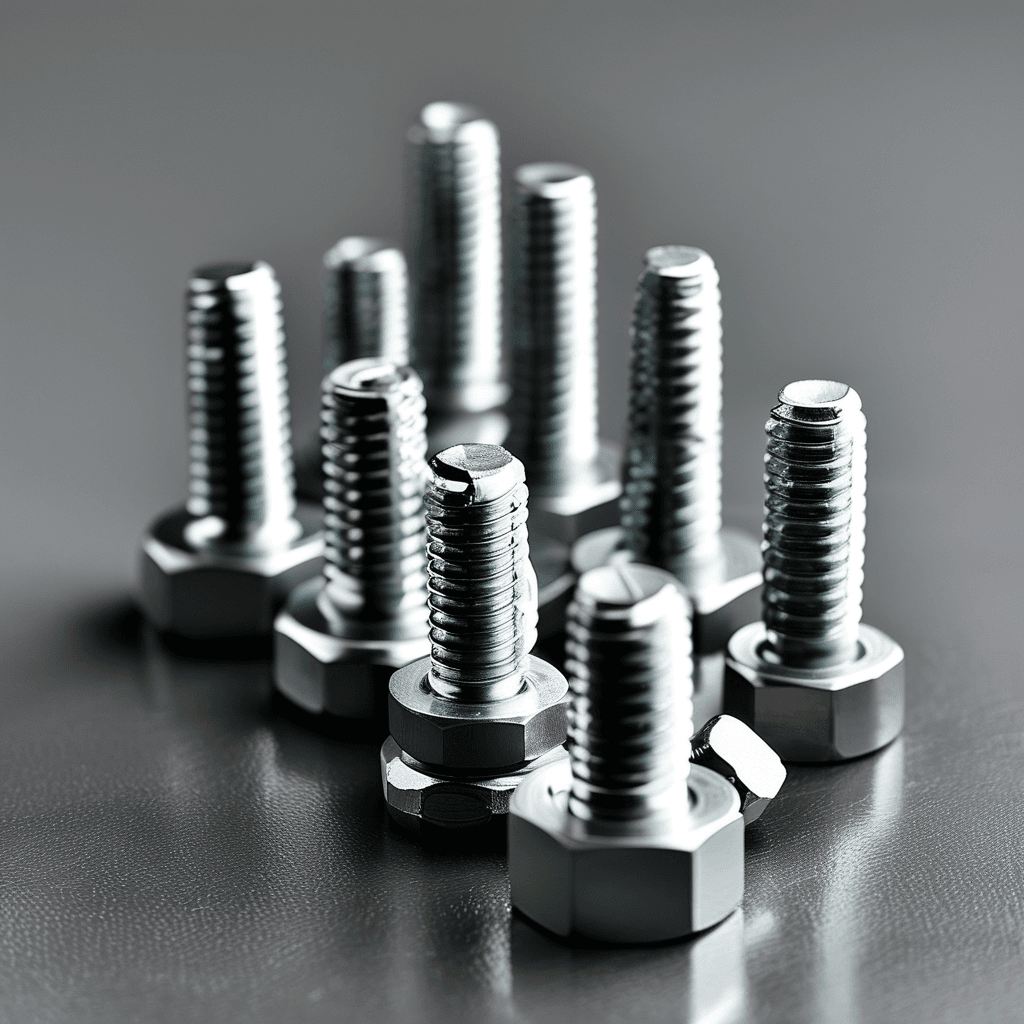

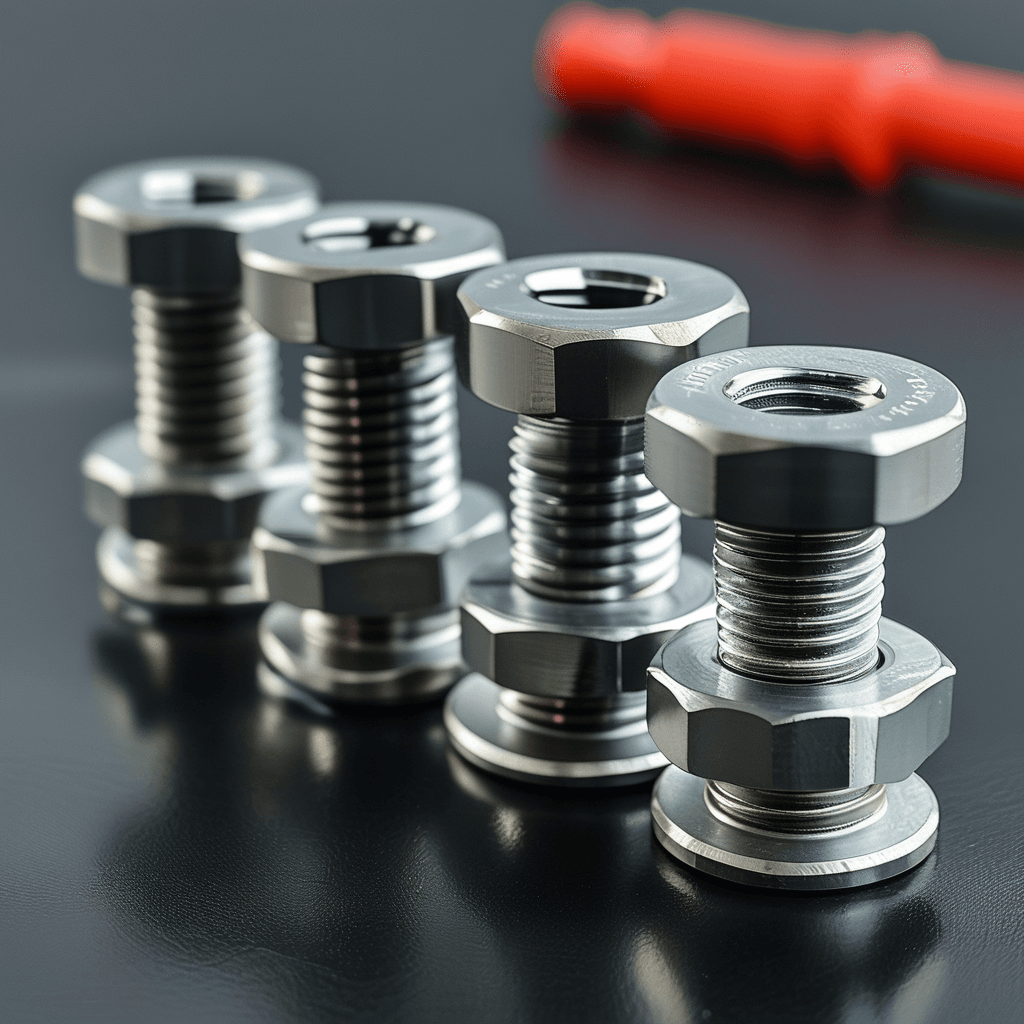

• Fasteners & Hardware

• Hinges & Connectors

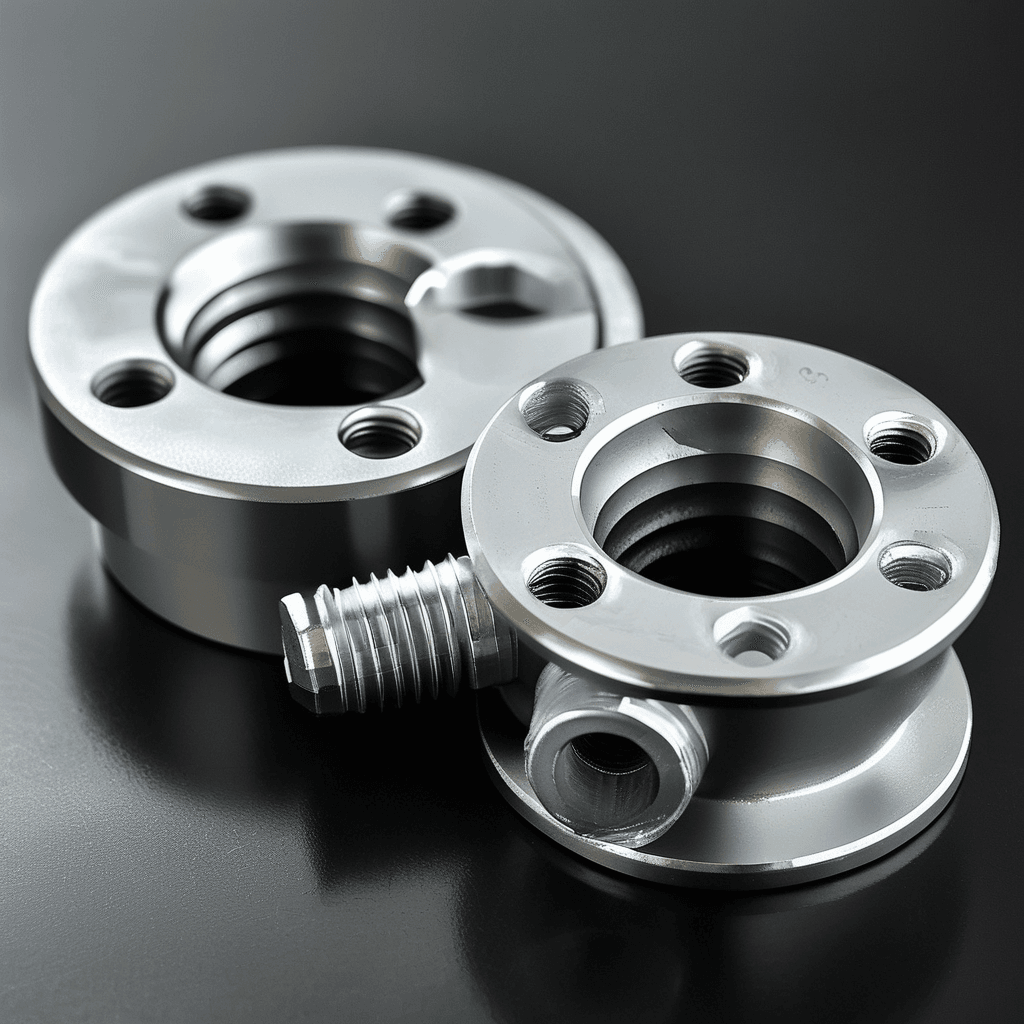

• Door & Latch Fittings

• Seat Component Parts

• Environmental components

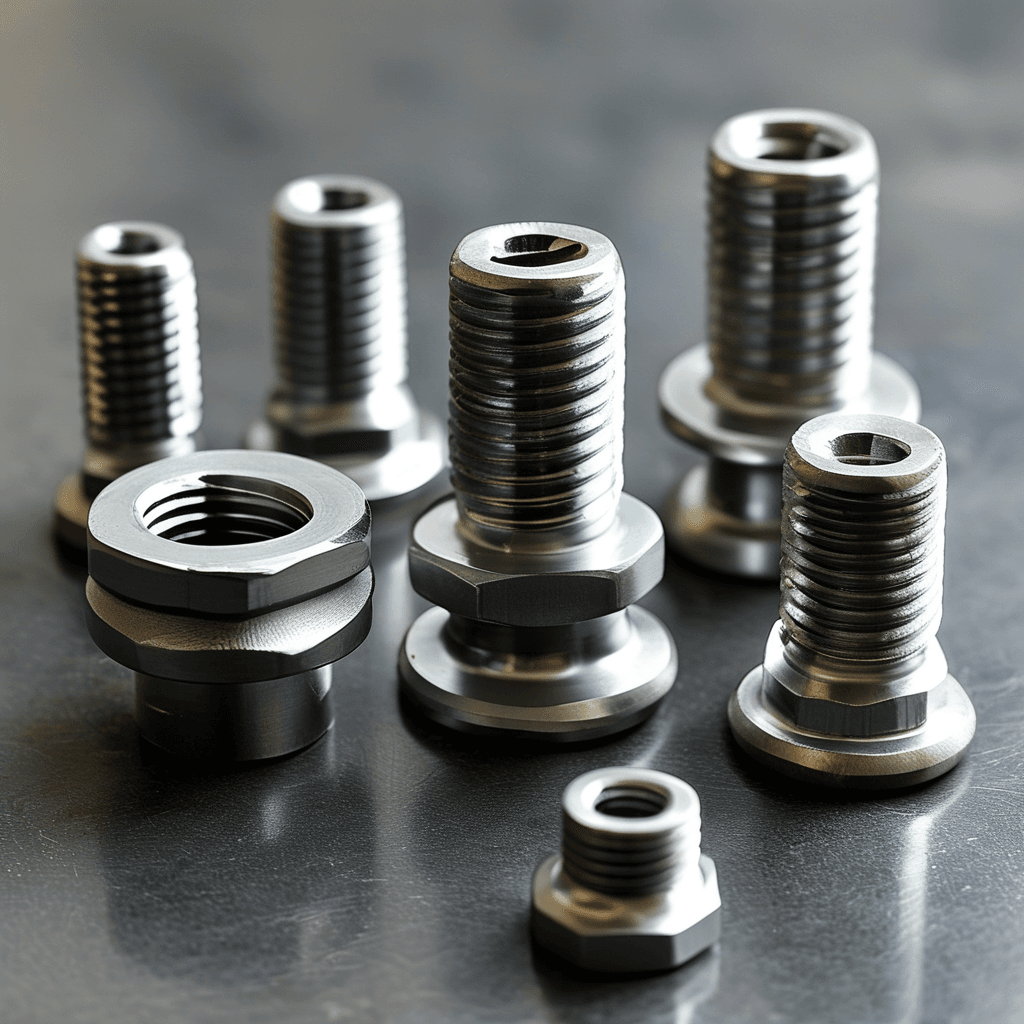

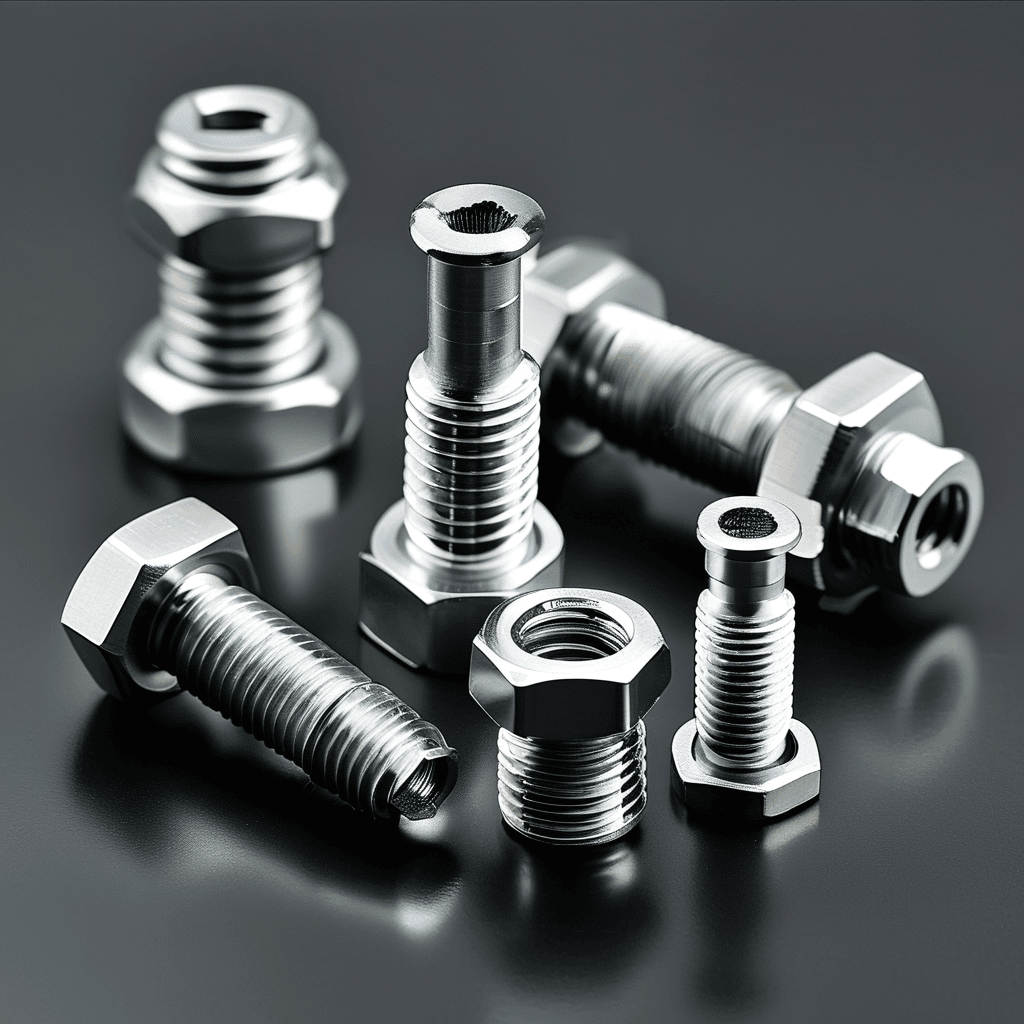

Aerospace MRO Titanium Alloy Fasteners

High Strength · Lightweight · Extreme Environment Resistant

Product Overview

Our titanium alloy fasteners are engineered for the Aerospace Maintenance, Repair, and Overhaul (MRO) market. Manufactured from high-performance alloys like TC4 (Ti-6Al-4V) and TC6, they comply with AS9100D and NADCAP certifications, ensuring reliability for commercial aircraft, military aviation, and spacecraft structural applications.

Key Advantages

✅ Superior Strength-to-Weight Ratio: 45% lighter than steel with comparable strength, reducing aircraft fuel consumption (*saving ~3,000 gallons/year per 1kg weight reduction*).

✅ Exceptional Corrosion Resistance: Withstands salt spray, humidity, and chemical exposure, minimizing replacement frequency.

✅ Extreme Temperature Tolerance: Stable performance from -250°C to 600°C, ideal for engine compartments and landing gear.

✅ Fatigue Resistance: 1M+ cycle testing with zero cracks, ensuring flight safety.

Market Data & Demand Trends

2024 Global MRO Market: Projected at $1.02 trillion (2023–2032), with growing titanium fastener adoption.

2030 Forecast: Aerospace titanium fasteners to reach $5.48 billion, CAGR 7.6% (Straits Research, 2024).

Growth Drivers:

New-gen aircraft (e.g., C919, Boeing 787) use 15% titanium vs. 3–9% in legacy models.

Military drones/hypersonic vehicles demand specialty fasteners.

Product Range

| Type | Applications | Standards |

|---|---|---|

| Titanium Bolts/Nuts | Airframe load-bearing structures | ASTM F468, AMS 4928 |

| Titanium Rivets (CR Series) | Skin panel assembly, door hinges | NASM 25027, GB/T 3098.10 |

| Hi-Lok Fasteners | Composite jointing (e.g., A350XWB) | BACB30LT |

| Shear Pins | Pylon emergency release systems | COMAC C919 Airworthiness |

Why Choose Us?

✔ Localization Leader: Supplied 20% of C919 titanium fasteners with >70% domestic content.

✔ Rapid Delivery: 72-hour samples from Asian hubs; 30% shorter lead time vs. competitors.

✔ Cost-Effective: 15–20% lower cost than EU/US suppliers; MOQ 500pcs.

✔ Lifecycle Support: NDT reports, failure analysis, and remanufacturing solutions.