Titanium Heat Exchangers & Condenser Systems

Proven Applications

✔ Marine & Offshore: Titanium condensers for FPSO vessels, seawater cooling (20+ year lifespan).

✔ Chemical Processing: Chlor-alkali plants, HCl/acid heat recovery (zero corrosion after 10+ years).

✔ Medical & HVAC: Ultra-hygienic, non-reactive titanium for implant manufacturing and heat pumps.

Titanium Heat Exchangers & Condenser Systems – High-Performance Solutions for Demanding Industries

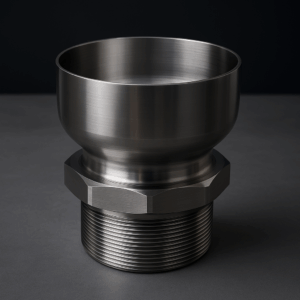

Superior Corrosion Resistance & Longevity

Our titanium heat exchangers and condensers are engineered for extreme environments, offering 10x greater corrosion resistance than 316L stainless steel in chloride-rich media (e.g., seawater, acids). With a PREN (Pitting Resistance Equivalent Number) >40, they outperform conventional materials in aggressive chemical, marine, and oil & gas applications.

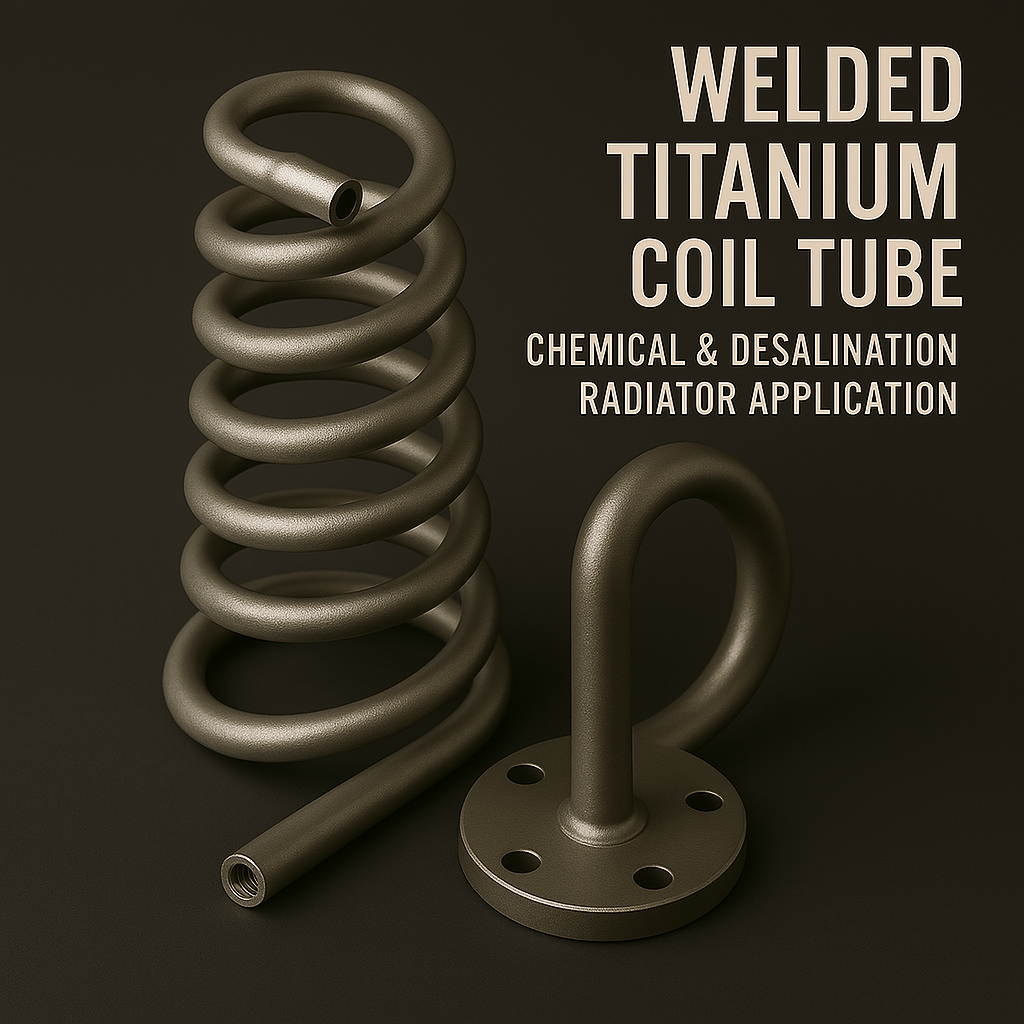

Enhanced Thermal Efficiency

- Spiral-wound titanium tube designs achieve 8,000–12,000 W/(m²·℃) heat transfer coefficients, improving energy efficiency by 30–50% compared to traditional shell-and-tube models.

- 3D turbulence flow technology reduces fouling, extending maintenance intervals to 2+ years in saltwater and chemical processing.

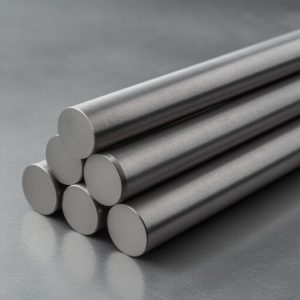

Lightweight & High Strength

- Density: 4.5 g/cm³ (60% lighter than steel) with 900 MPa tensile strength, ideal for aerospace, shipbuilding, and compact industrial systems.

- Wide temperature range (-253°C to 500°C), suitable for LNG cryogenics and high-temperature processes.

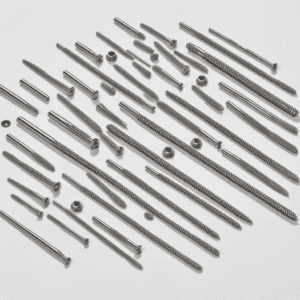

Smart & Customizable Solutions

- IoT-integrated sensors enable real-time performance monitoring, predictive maintenance, and 98% fault detection accuracy.

- Custom fabrication (TA1, Gr2, Gr5 titanium) for shell & tube, plate, and spiral designs, with OEM/ODM support.

Why Choose Us?

✅ ISO 9001, CE, ASTM/AMS certified

✅ 30% cost savings vs. US/EU suppliers (FOB China)

✅ Fast lead time (3–4 weeks), small MOQ (1 ton)

Request a Quote Today – Optimize Your Thermal Systems with Titanium Excellence!