wheel hub assemblies

Certifications & Compliance

Our titanium fasteners meet:

ASTM B348 / AMS 4928 (Aerospace-grade standards)

IATF 16949 (Automotive quality management)

RoHS & REACH (Environmental compliance)

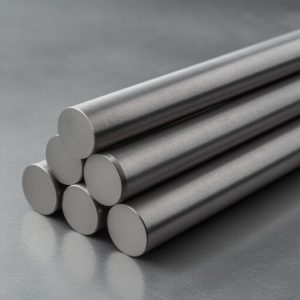

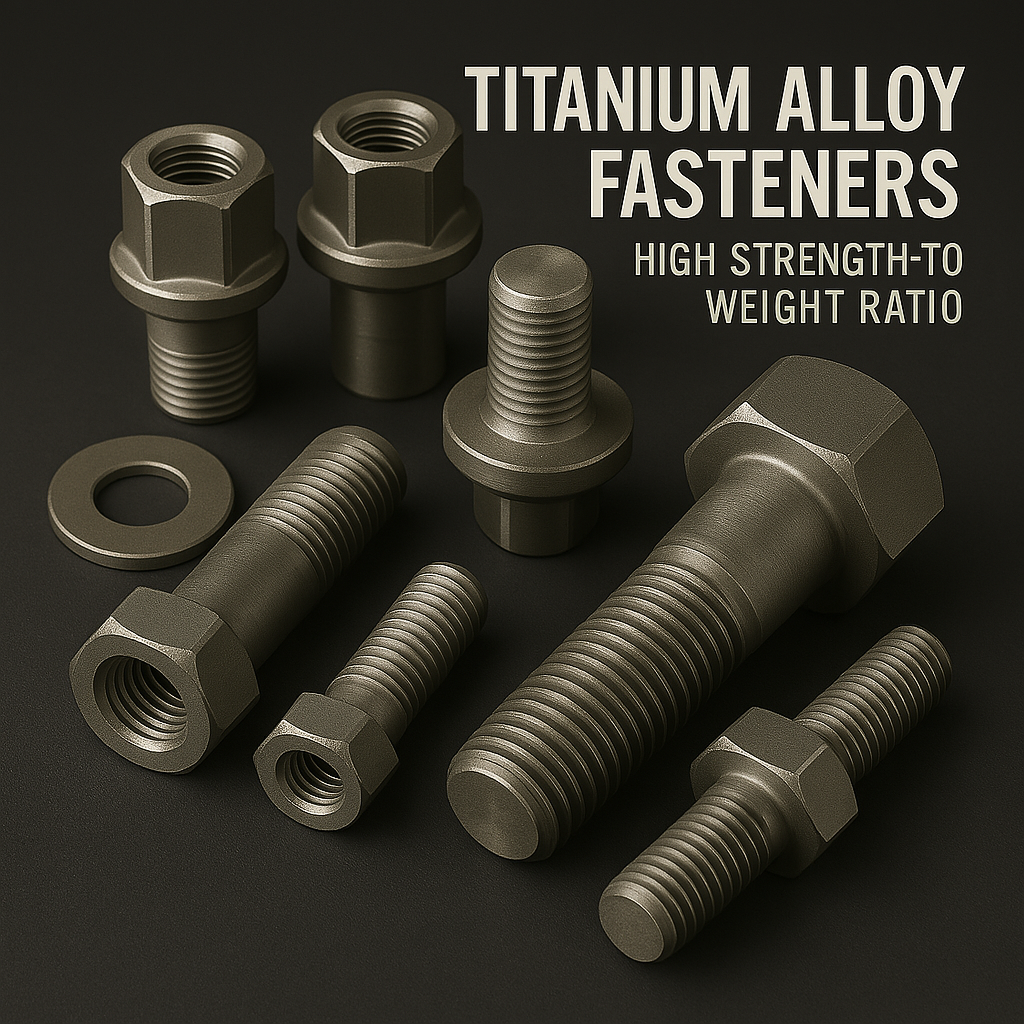

Titanium Alloy Fasteners for Automotive Applications

Premium Performance for Demanding Automotive Environments

Our titanium alloy fasteners are engineered to meet the highest standards of strength, durability, and weight efficiency, making them ideal for automotive applications where performance and reliability are critical. With a 7.1% CAGR projected from 2024 to 2030, the global titanium fastener market is expanding rapidly, driven by demand in high-performance vehicles, electric cars, and motorsports9.

Why Choose Titanium Fasteners for Automotive Use?

✔ Lightweight – Up to 40% lighter than steel, improving fuel efficiency and reducing emissions.

✔ High Strength-to-Weight Ratio – Superior tensile strength for critical load-bearing applications.

✔ Exceptional Corrosion Resistance – Ideal for harsh environments, including saltwater and chemical exposure.

✔ Thermal Stability – Maintains integrity under extreme temperatures, perfect for EV battery systems and exhaust components.

Applications in the Automotive Industry

Electric Vehicles (EVs) – Battery housings, motor mounts, and structural components benefit from titanium’s lightweight and durability.

Performance & Motorsports – Titanium bolts, nuts, and screws are widely used in racing vehicles for weight reduction and reliability.

High-End & Luxury Cars – Manufacturers opt for titanium fasteners in suspension systems, chassis reinforcement, and high-stress joints.

Market Trends & Demand

The global titanium fastener market is expected to reach $4.1 billion by 2030, with automotive applications playing a key role.

Aerospace-grade titanium fasteners are increasingly adopted in automotive due to their proven reliability in extreme conditions.

Leading automakers and Tier 1 suppliers are shifting to titanium for lightweighting initiatives, especially in EVs and hybrid models.

Custom Solutions Available

We offer tailored titanium fasteners in various grades (Gr. 2, Gr. 5, Gr. 9) and configurations (bolts, nuts, washers, custom machined parts).

Contact us today to discuss how our titanium fasteners can enhance your automotive designs with unmatched performance and efficiency.