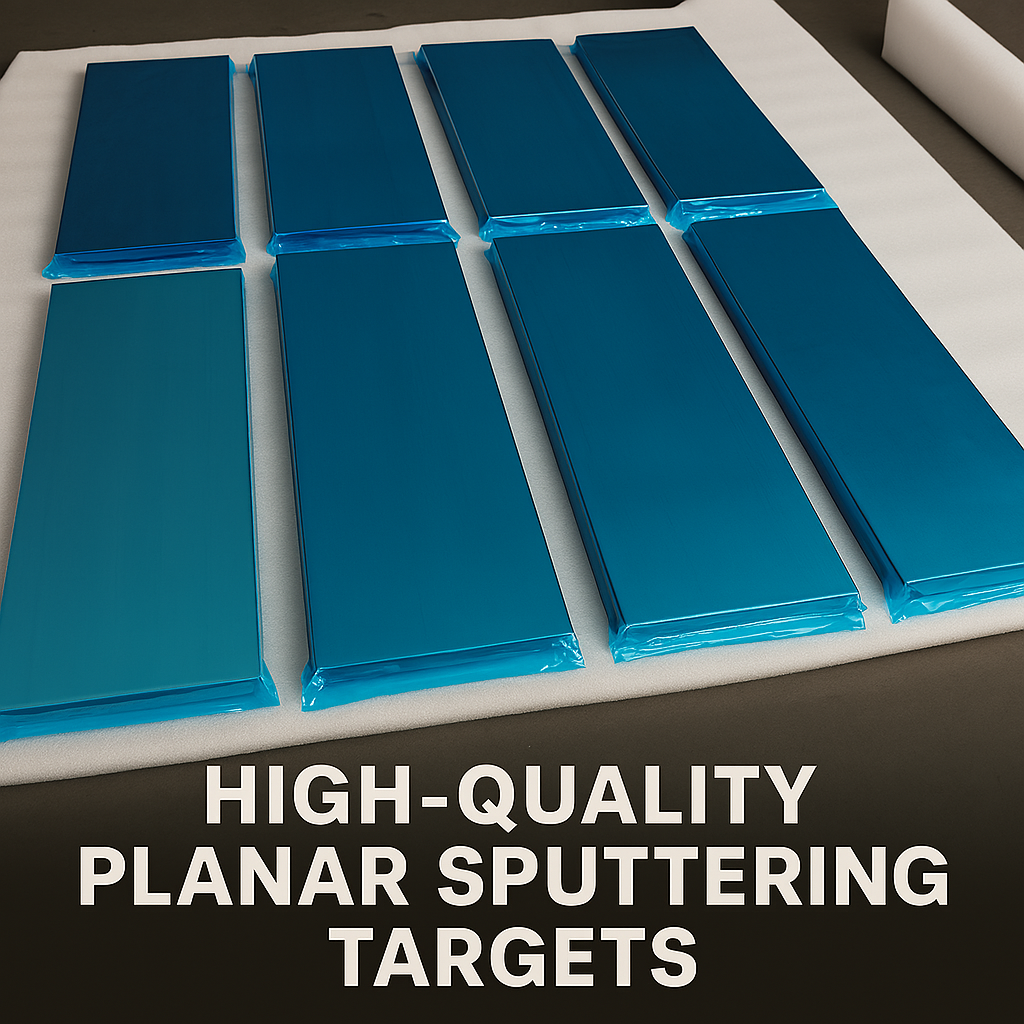

Chemical Product Introduction: Sputtering Targets

High-Purity Titanium Vacuum Coating Targets (Sputtering Targets)

Grades: Ti 99.9% (3N), Ti 99.99% (4N), Ti 99.999% (5N)

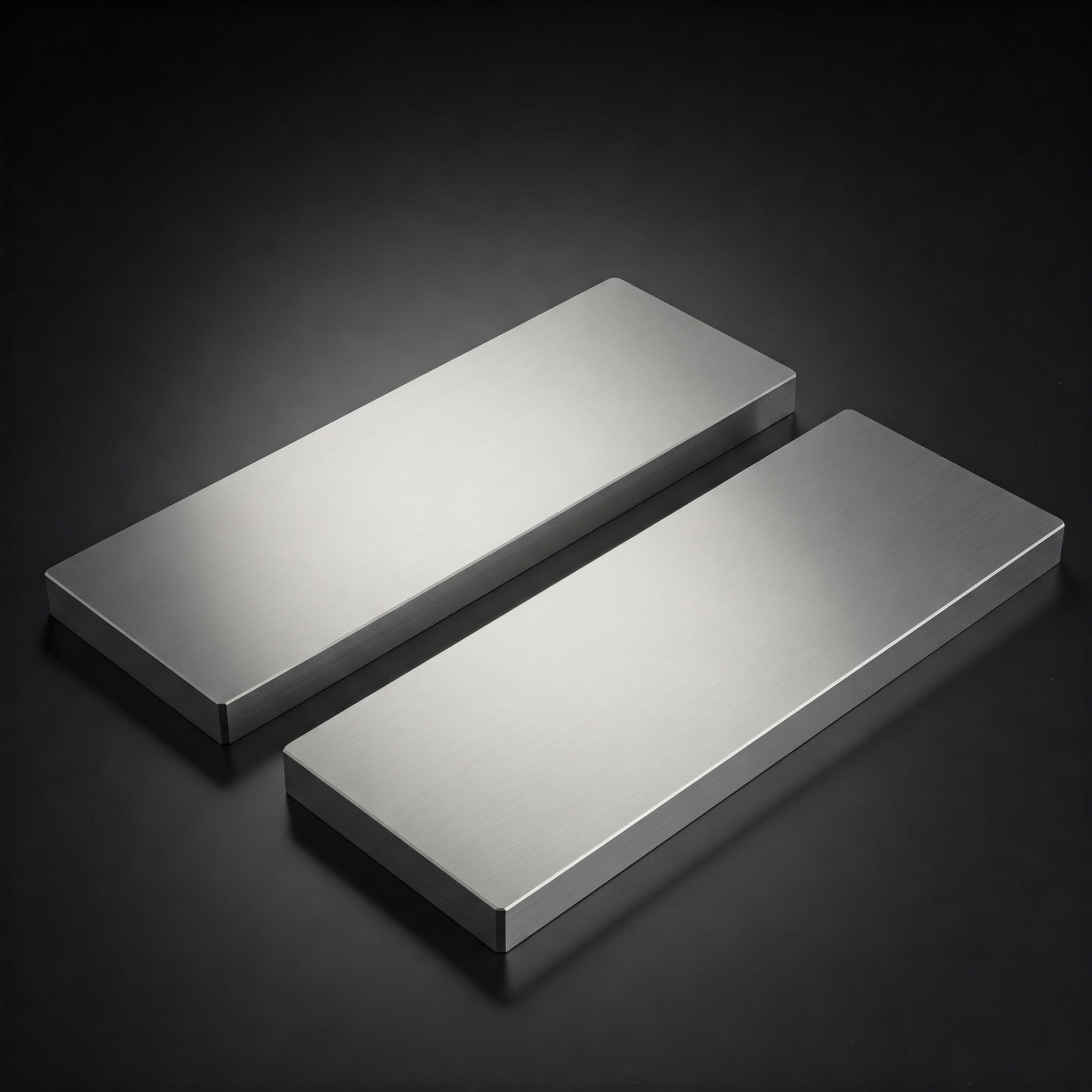

Shapes: Round targets (Ø50mm–Ø300mm), Rectangular plate targets (Max. 600×1200mm), Tube targets (custom sizes).

Applications: Semiconductor thin films, optical coatings, solar PV, display panels (OLED/TFT), decorative coatings.

Key Technical Specifications (International Standards)

1. Chemical Composition

| Element | Ti 99.9% (ppm) | Ti 99.99% (ppm) | Ti 99.999% (ppm) |

|---|---|---|---|

| Fe | ≤500 | ≤50 | ≤5 |

| O | ≤800 | ≤100 | ≤10 |

| C | ≤100 | ≤30 | ≤5 |

| N | ≤50 | ≤20 | ≤5 |

| Other impurities | ≤700 | ≤100 | ≤20 |

2. Mechanical Properties

| Parameter | Typical Values |

|---|---|

| Density | 4.51 g/cm³ |

| Tensile Strength | 240–350 MPa |

| Vickers Hardness (HV) | 90–120 |

| Grain Size | ≤50μm (custom ≤20μm) |

3. Physical Specifications

Grain Size Control: Optimized via HIP (Hot Isostatic Pressing) or forging (SEM reports available).

Surface Finish:

Polished: Ra ≤0.4μm (mirror finish, ideal for optical coatings).

Machined: Ra ≤1.6μm (standard industrial grade).

Flatness: ≤0.05mm/100mm (laser interferometer tested).

Bonding Compatibility: Pre-bonded with Cu/Al backing plates (optional).

Quality Assurance & Certifications

Testing Standards: ASTM B265 (plate), ASTM F67 (medical grade), JIS H4600.

Certificates: Third-party lab reports (SGS/BV), material traceability certificates.

Packaging: Vacuum-sealed + shock-proof wooden crates (ISO shipping compliant).

Buyer’s Guide

Material Selection:

Semiconductors/PV: Use 4N/5N grade (O≤10ppm).

Decorative Coatings: Cost-effective 3N grade suffices.

Lead Time:

Standard sizes: 7–15 days (in-stock).

Custom sizes: 30–45 days .

Technical Support: Free sputtering parameter recommendations (e.g., DC/RF power, substrate temperature).