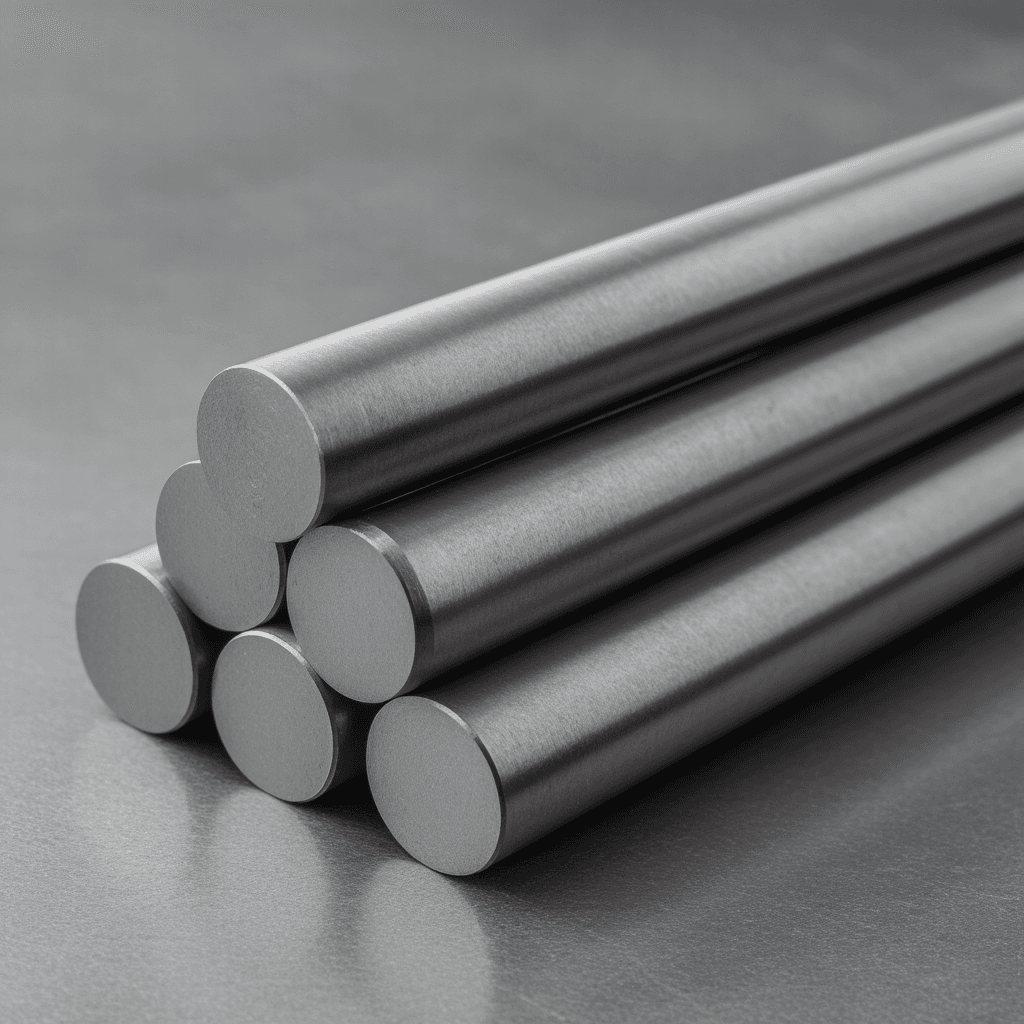

titanium bars for 3D printing engineering

Applications

- Aerospace: Turbine blades, structural components, and lightweight aircraft parts.

- Medical: Orthopedic implants, dental prosthetics, and surgical instruments.

- Automotive: High-performance racing components and lightweight structural parts.

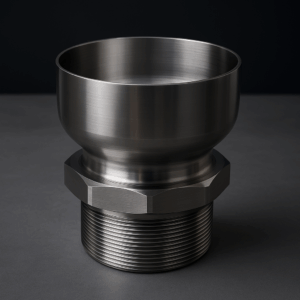

- Industrial: Corrosion-resistant valves, pumps, and energy sector applications.

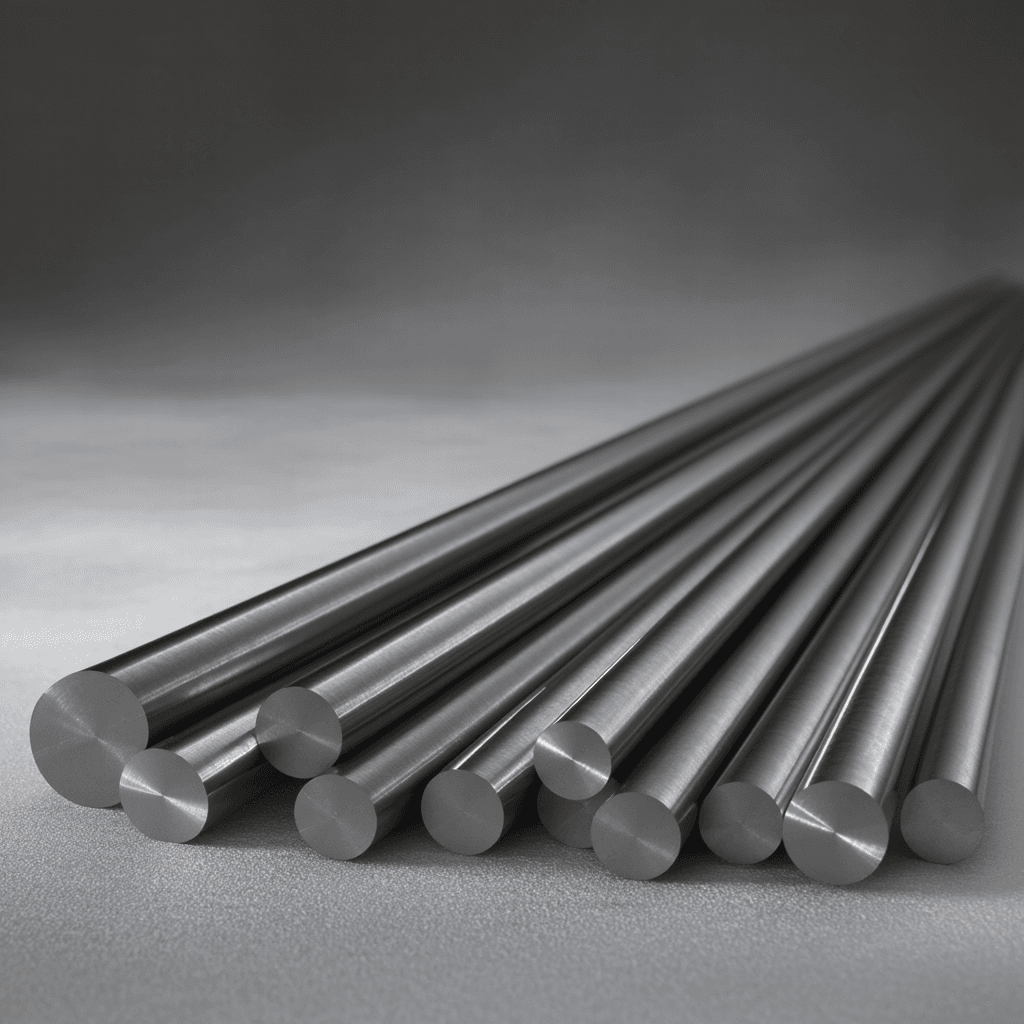

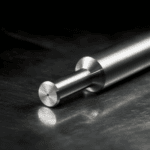

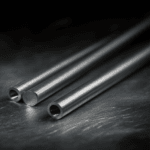

3D Printing Titanium Rods – High-Performance Material for Additive Manufacturing

Product Overview

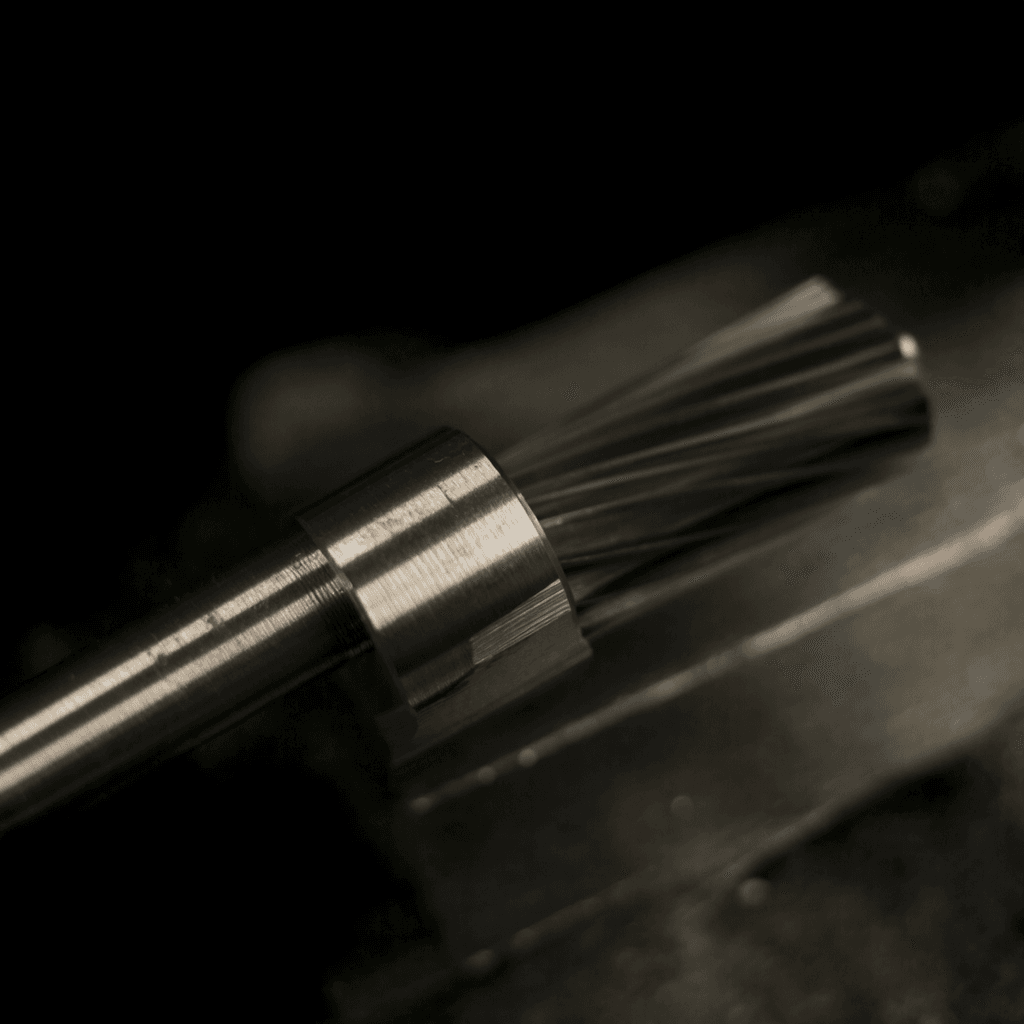

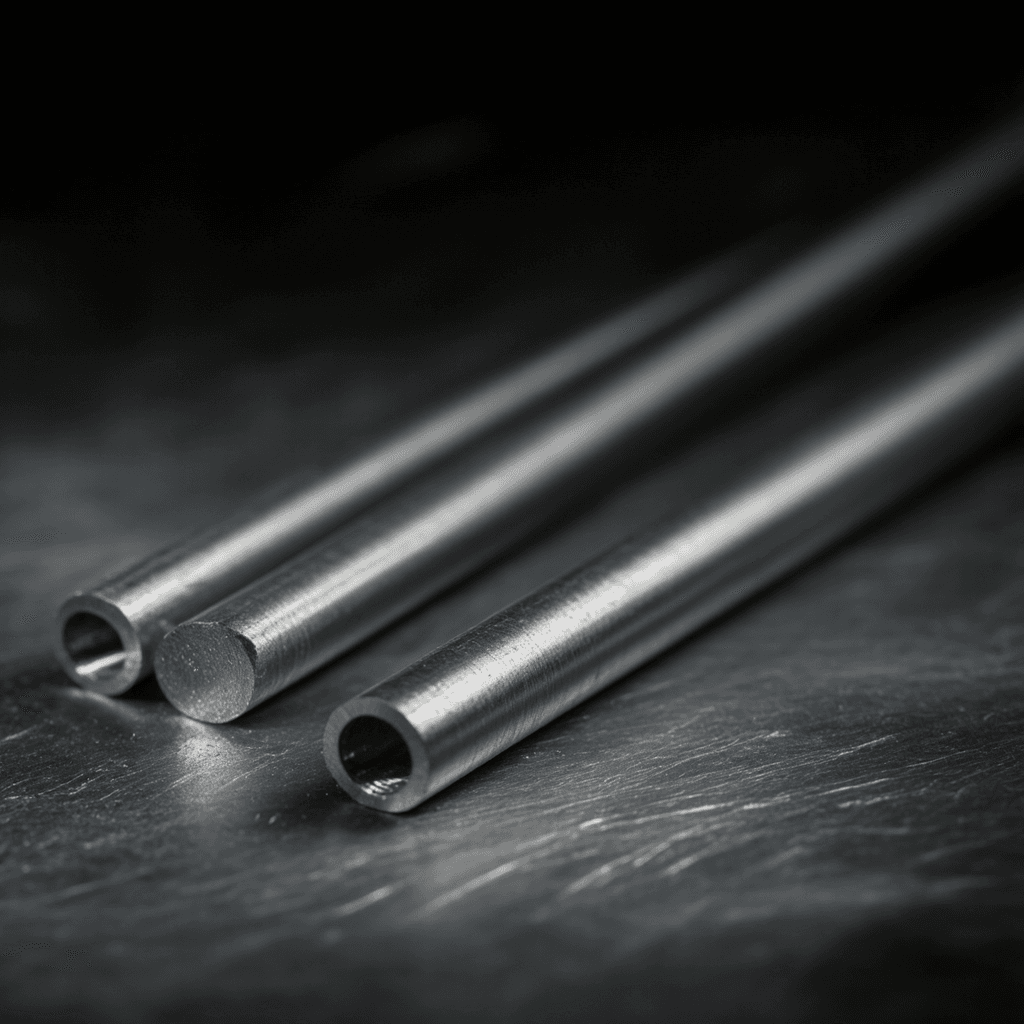

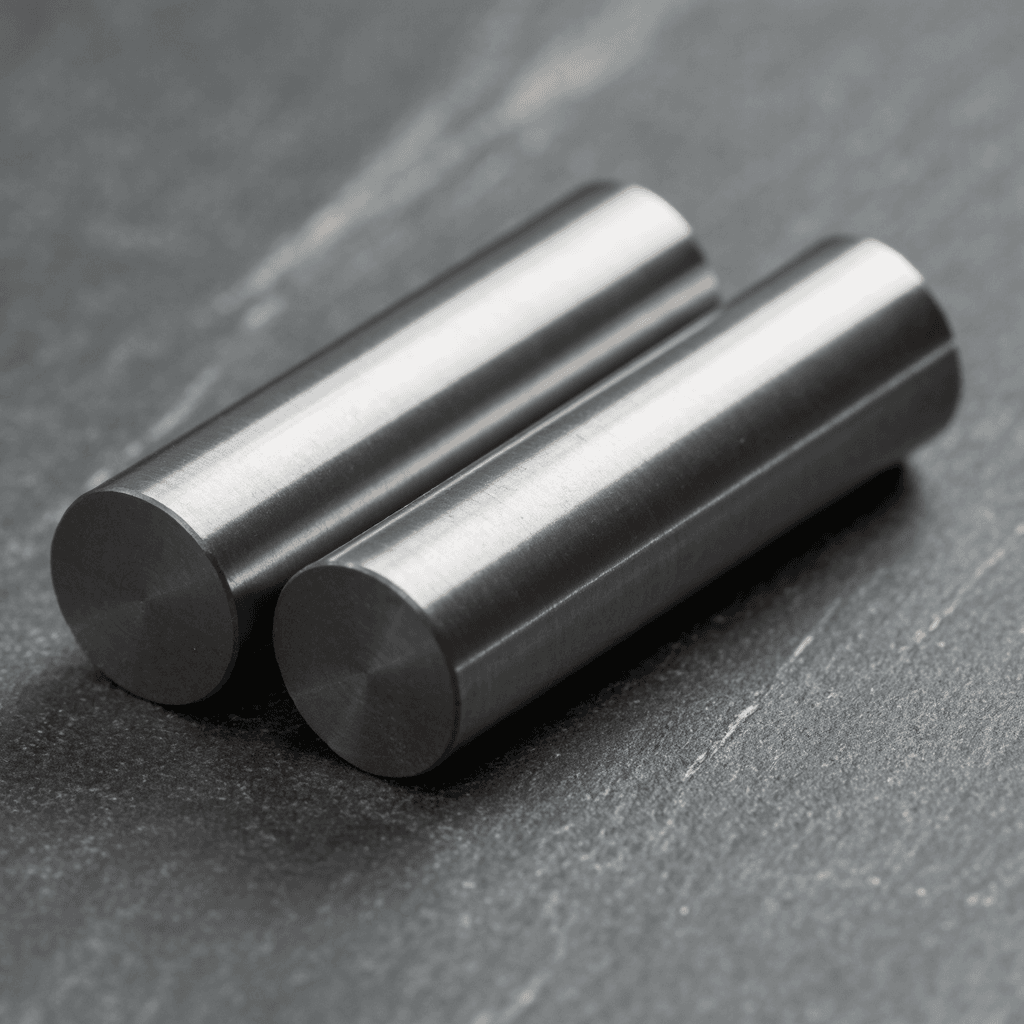

Our 3D printing titanium rods are precision-engineered for additive manufacturing (AM) applications, offering superior mechanical properties, corrosion resistance, and biocompatibility. Made from Grade 5 (Ti-6Al-4V / TC4), Grade 23 (Ti-6Al-4V ELI), and TA15 titanium alloys, these rods are ideal for aerospace, medical implants, automotive, and industrial 3D printing processes such as:

- Plasma Rotating Electrode Process (PREP)

- Gas Atomization (GA)

- Electron Beam Melting (EBM)

- Selective Laser Melting (SLM)

Key Features & Benefits

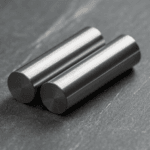

✅ High Purity & Consistency – Manufactured using triple vacuum arc remelting (VAR) to ensure minimal impurities and uniform microstructure.

✅ Excellent Mechanical Properties – Tensile strength ≥895 MPa, elongation ≥10%, meeting ASTM B348, AMS 4928, and GB/T 2965 standards.

✅ Customizable Dimensions – Available in diameters 10mm–100mm, lengths up to 1000mm, with tight tolerances for seamless powder production.

✅ Ultrasonic Tested – 100% inspected for internal defects (no cracks, inclusions, or porosity).

Why Choose Our Titanium Rods?

✔ Cost-Effective – Competitive pricing compared to US/EU suppliers, with 30% lower lead times.

✔ Global Compliance – Certified to ISO 9001, AS9100, and PED for aerospace and medical industries.

✔ Fast Turnaround – Samples available upon request, bulk production in 2–4 weeks.