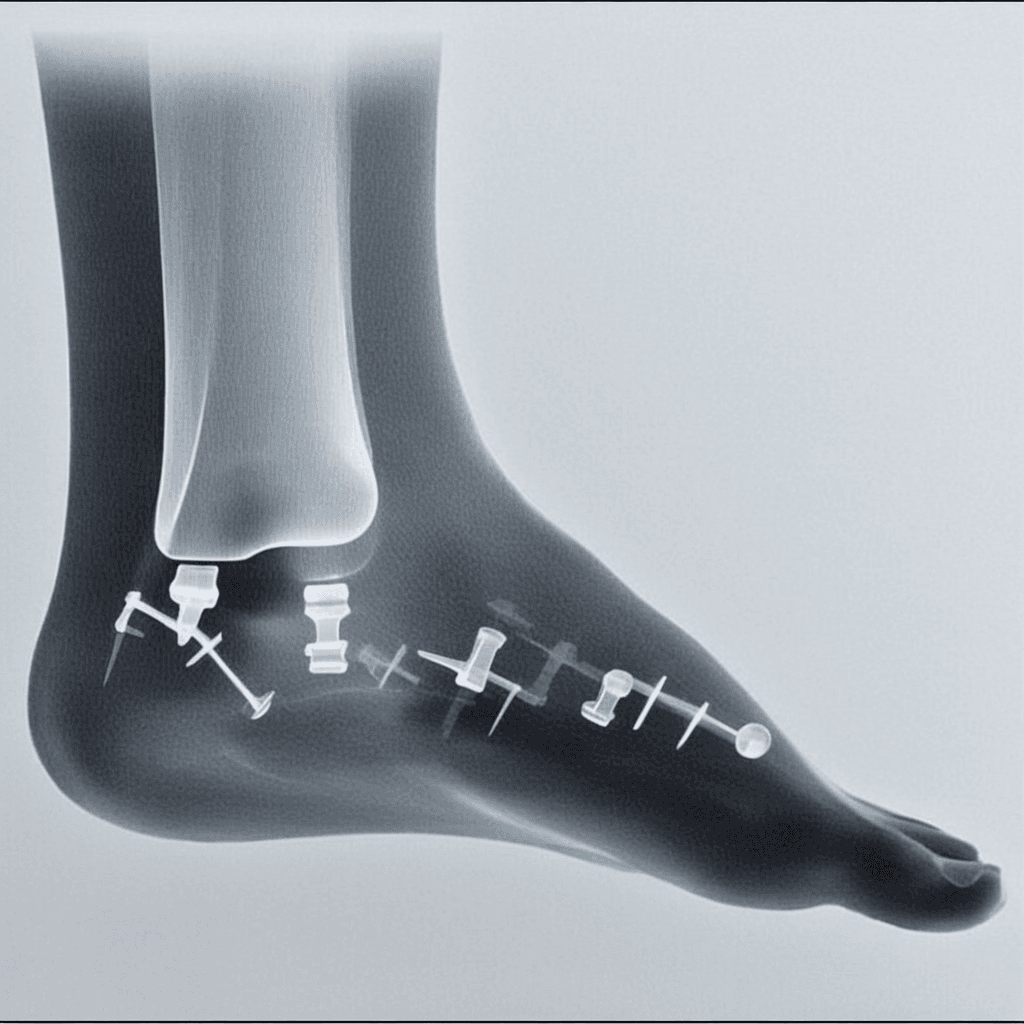

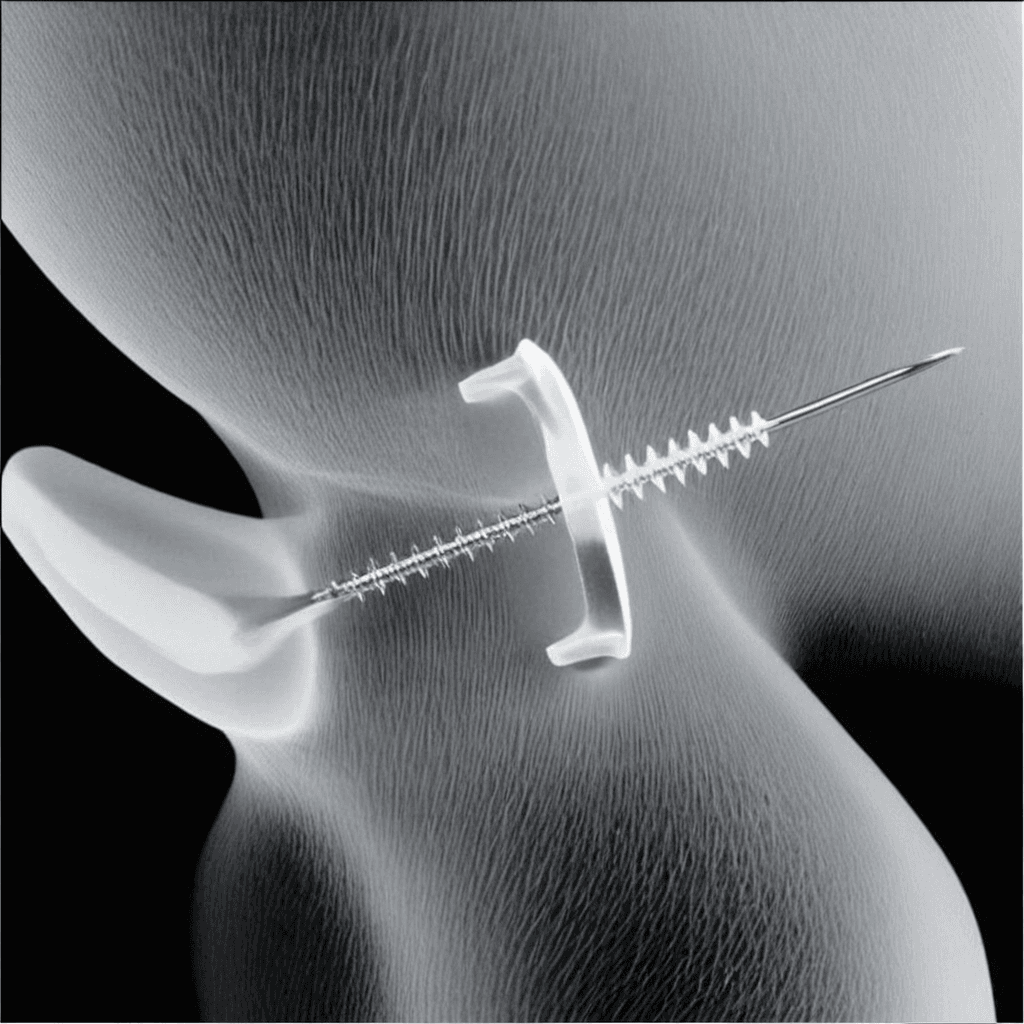

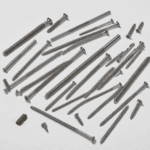

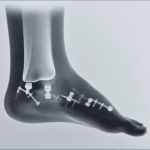

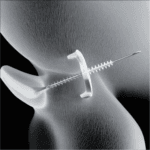

Prego ósseo e placa óssea para cirurgia de fratura

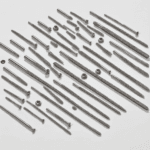

Titanium and its alloys are known for their high strength, low weight, and excellent resistance to corrosion, making them valuable in various industries, especially in medical applications. Each year, over 1000 tonnes of titanium devices are implanted in patients all over the world. The demand for joint replacements is increasing due to longer lifespans and injuries from activities like sports or accidents. Titanium is lightweight, strong, and exceptionally compatible with the human body, which makes it ideal for implants.

Medical-grade titanium alloys have a better strength-to-weight ratio than stainless steels. Various titanium alloys allow medical designers to choose the best materials for specific needs, ranging from highly ductile pure titanium for ease of shaping to heat-treatable alloys with high strength. Shape-memory alloys also add to the range of properties for medical use. Many processes including forging, casting, machining, and surface engineering are employed to enhance the performance of titanium products.

For implants in the human body, reliability is crucial since they cannot be easily maintained or replaced. Titanium’s corrosion resistance ensures that it does not release harmful metallic ions, making it inert and fully compatible with body tissues, which is essential for patient safety.

Materials available:

ASTM F67 Part 2 Unalloyed titanium-CP Grades 1-4 (ASTM F1341 specifies wire)

ASTM F136 Part 3 Ti-6AI-4V ELI wrought(ASTM F620 specifies forgings)

ASTM F1295 Part 11 Ti-6AI-7Nb wrought

ASTM F1713 Ti-13Nb-13Zr Wrought

ASTM F1813 Ti-12Mo-6Zr-2Fe Wrought