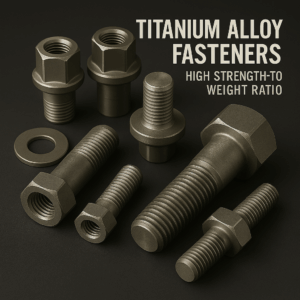

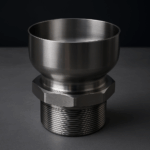

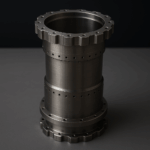

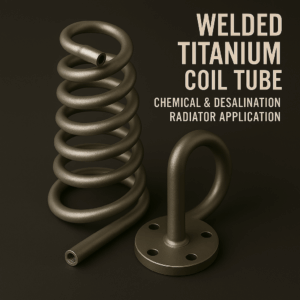

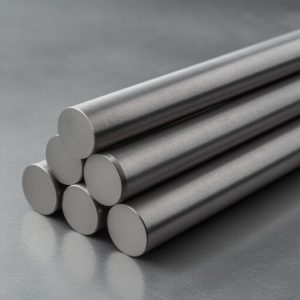

Titanium Alloy Precision Machinery Parts

Product Overview

Our lightweight, high-strength titanium alloy precision parts, manufactured from Ti-6Al-4V (Grade 5), deliver exceptional performance in demanding environments. Engineered for precision, these components meet stringent aerospace, medical, and industrial standards.

Key Features

Lightweight: Density of 4.43 g/cm³, ~60% of steel, reducing overall system weight.

High Strength: Tensile strength 900-1000 MPa, yield strength ~830 MPa.

Corrosion Resistance: Superior resistance to saline, acidic, and high-temperature environments.

Thermal Stability: Operates effectively from -250°C to 400°C.

Biocompatibility: Non-toxic, ideal for medical implants.

Chemical Composition (Ti-6Al-4V)

Titanium (Ti): Balance

Aluminum (Al): 5.5-6.75%

Vanadium (V): 3.5-4.5%

Iron (Fe): ≤0.25%

Oxygen (O): ≤0.2%

Physical Properties

Melting Point: 1604-1660°C

Modulus of Elasticity: 113.8 GPa

Thermal Conductivity: 6.7 W/m·K

Hardness: 36 HRC (typical)

Common Applications

Aerospace: Fasteners, landing gear components, engine blades, structural frames.

Медицинский: Orthopedic implants, surgical instruments.

Marine: Propeller shafts, desalination components.

Automotive: High-performance engine parts, suspension springs.

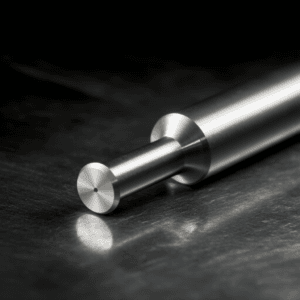

Manufacturing Process

Material: Premium Ti-6Al-4V ingots.

Machining: 5-axis CNC precision machining, tolerances ±0.01 mm.

Surface Treatment: Polishing, anodizing, or passivation for enhanced durability.

Quality Control: Non-destructive testing (NDT), ultrasonic, and X-ray inspection.

Compliance Standards

Aerospace: AMS4928, AMS4965, MIL-T-9047.

Медицинский: ASTM F136, ISO 5832-3.

General: ASTM B348, ASME SB-348.

Why Choose Our Ti-64 Precision Parts?

Certified quality with full traceability.

Customizable dimensions and geometries.

Proven reliability in extreme conditions.

For inquiries or custom orders, contact us at sales_yeung@tinog.com.cn